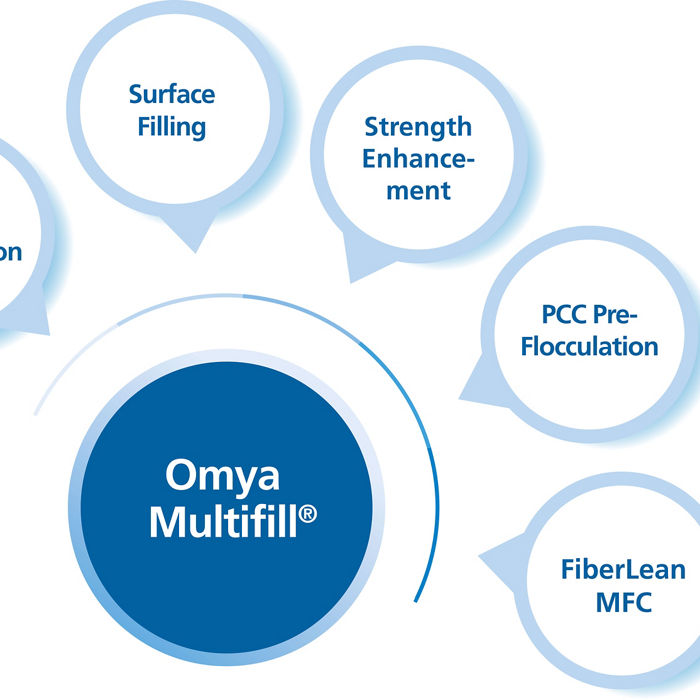

Tailored for the graphical paper and board industry, the Omya Multifill concept enables producers to replace fiber furnish with significantly higher quantities of mineral filler without reducing productivity or paper quality. This adaptable approach takes calcium carbonate filler loading to the next level by carefully bundling and structuring different filler boosting techniques to optimize the impact of each technology component.

Omya Multifill Advantage

- Cost savings through fiber replacement, reduced energy demand and easier dewatering and drying at higher filler loads

- Enhanced runability through better wet strength properties

- Improved paper properties (physical and optical)

- Upgraded paper quality facilitating finishing, printing and further processing

- Creation of specific paper characteristics, opening new markets

- Improved competitiveness

%3ASmall-Landscape?ts=1704529562524&dpr=off)